RAD140 Purity Test Details: Behind the scenes guarantee of high quality products

As a manufacturer, product quality is fundamental to the survival of the enterprise, and for compounds such as RAD140 (Testolone), purity directly determines its effect and market competitiveness. Purity testing is an indispensable part of the production process. This article will reveal the rigorous process and technical details behind high purity products through a real RAD140 purity test process.

HPLC test: RAD140 purity standard

The purity detection of RAD140 powder mainly relies on high performance liquid chromatograph (HPLC). This device is a central tool for accurate analysis of the composition of chemical compounds. According to strict quality standards, each batch of RAD140 must be tested to a purity of more than 98% before it is considered a qualified product.

Detailed description of detection steps

The following is a typical RAD140 purity test:

1. Sample and dissolve

Before testing can begin, a sample of RAD140 powder, usually 50 mg, is taken from the finished production. The sample is then added with a specific solvent (solvent name not provided) and thoroughly mixed to a clear liquid. The quality of the dissolution directly affects the subsequent test results, so this link must be carefully operated to ensure that the sample is completely dissolved.

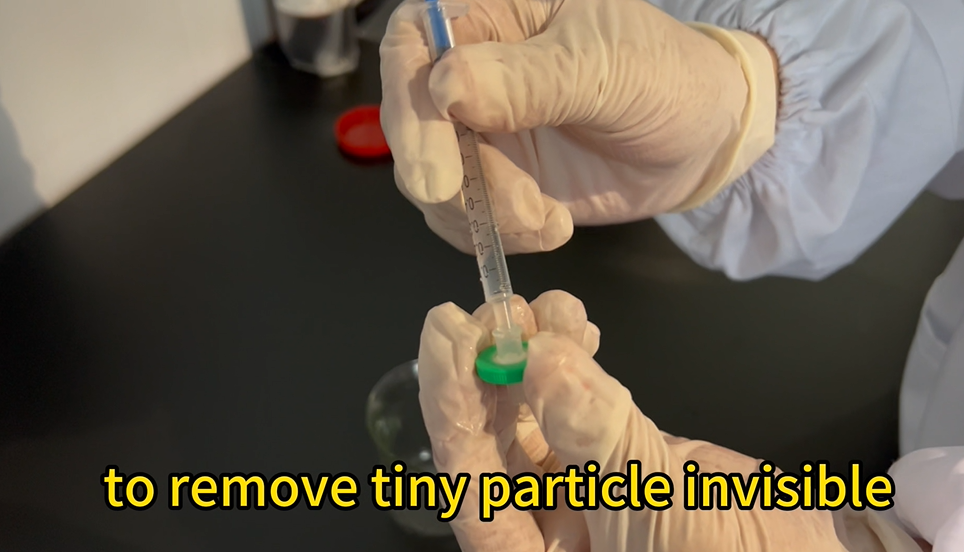

2. Sample filtration

The dissolved liquid sample needs to be treated with a filter membrane. The purpose of this step is to remove fine particles that are invisible to the naked eye and prevent them from affecting test results or clogging the C18 column in the HPLC instrument. The selection and use of the filter membrane also need to be precise to ensure that the sample purity meets the test standards.

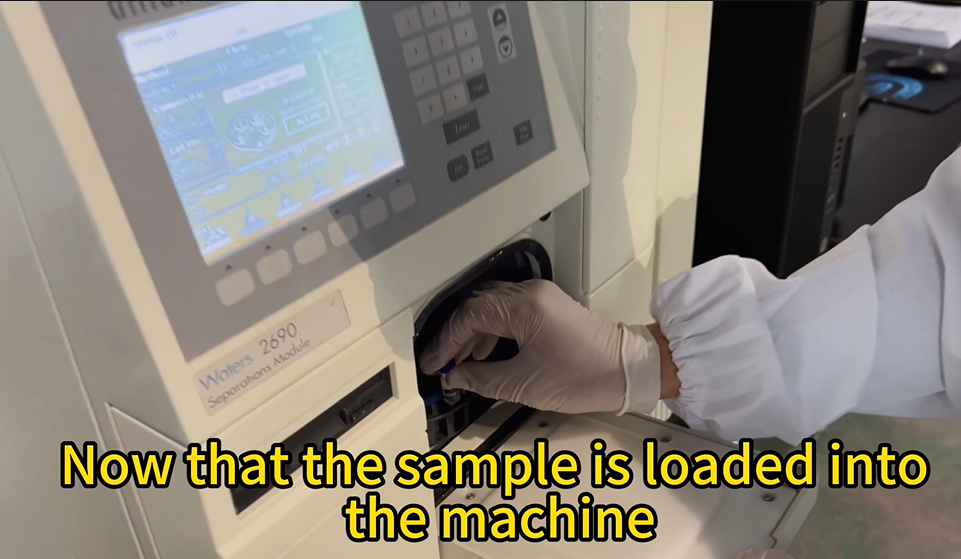

3. Inject the testing instrument

The filtered sample liquid is packed into a test bottle and then injected into an HPLC instrument via a syringe. This marks the completion of the sample preparation and the next step is instrument setup.

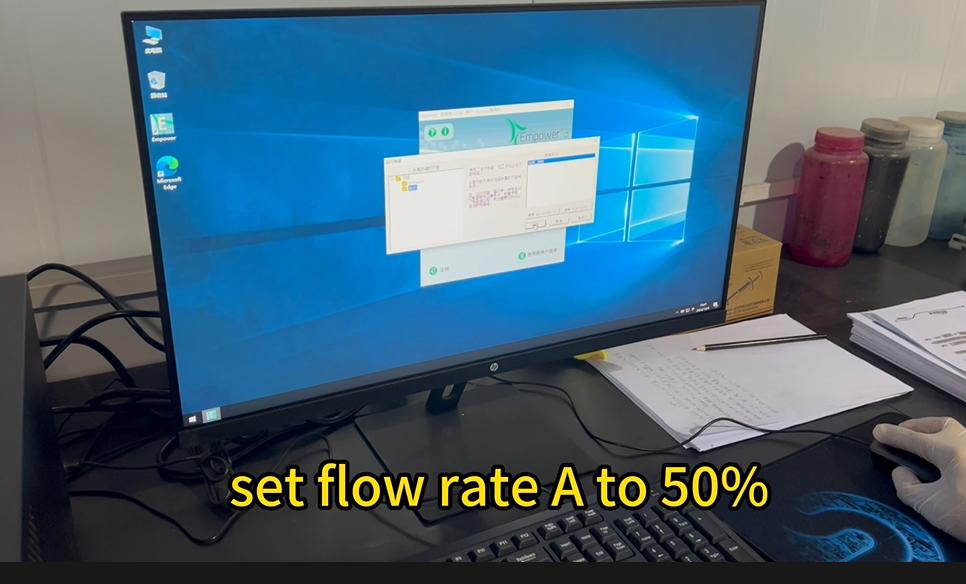

Instrument setup and testing

After placing the sample in the HPLC instrument, it needs to be set up according to the standard test procedure:

Traffic Settings: Set traffic to 50% for A, 0 for B, and 50% for C.

Column temperature setting: usually set to room temperature, that is, 30℃.

Sampling rate: Set to 10 to ensure the accuracy of data acquisition.

After all parameters are set, the instrument starts the test. At this point, HPLC separates and analyzes the sample composition by C18 column and produces a purity test result.

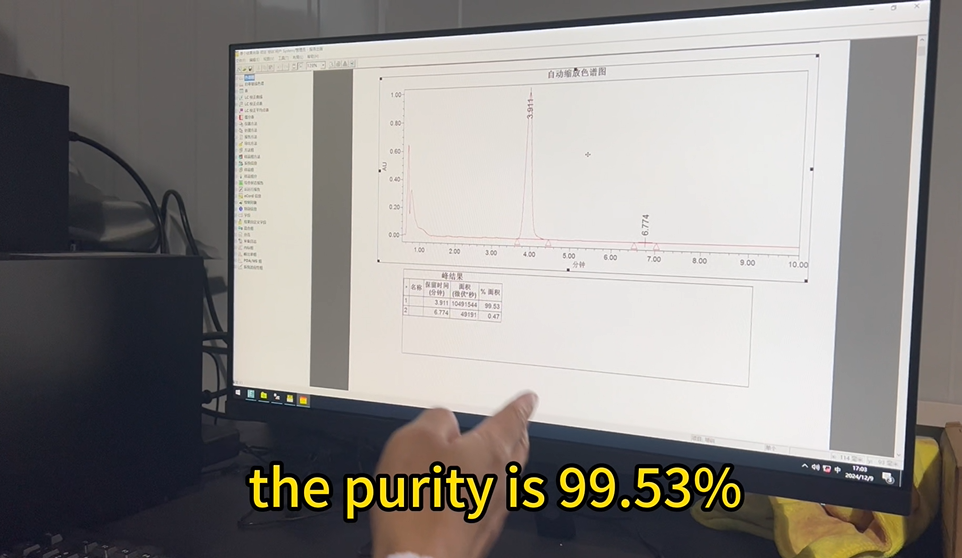

Test result: 99.53% high purity

After the test, the instrument showed that the purity of the RAD140 sample was 99.53%. This result shows that the product meets very high purity standards and provides customers with a safe and reliable experience. This not only validates the factory's production process, but also demonstrates the importance of a rigorous inspection process.

Conclusion

Through the above testing process, we can clearly see the professionalism and accuracy of the RAD140 purity test. From sampling to dissolution and filtration, to instrument setup and testing, each step requires a rigorous standardized process to ensure that the final purity data is true and reliable.

For manufacturers, high-quality RAD140 is not only a chip in the market competition, but also a responsibility and commitment to customers. For consumers, choosing products with HPLC testing certification is the key to protecting their own interests. After all, purity is not only a number, but also a reflection of quality and trust.

Video