LGD4033 Purification crystallization: Behind the scenes process of high purity powder

In the chemical research and preparation process, purification and crystallization are important steps to obtain high purity compounds. Taking LGD4033 (Ligandrol) as an example, its purification and crystallization process not only requires highly specialized equipment support, but also requires precise operation and scientific process management. This article will introduce in detail the process and technical points of LGD4033 purification crystallization, and show the technical details behind the high purity products.

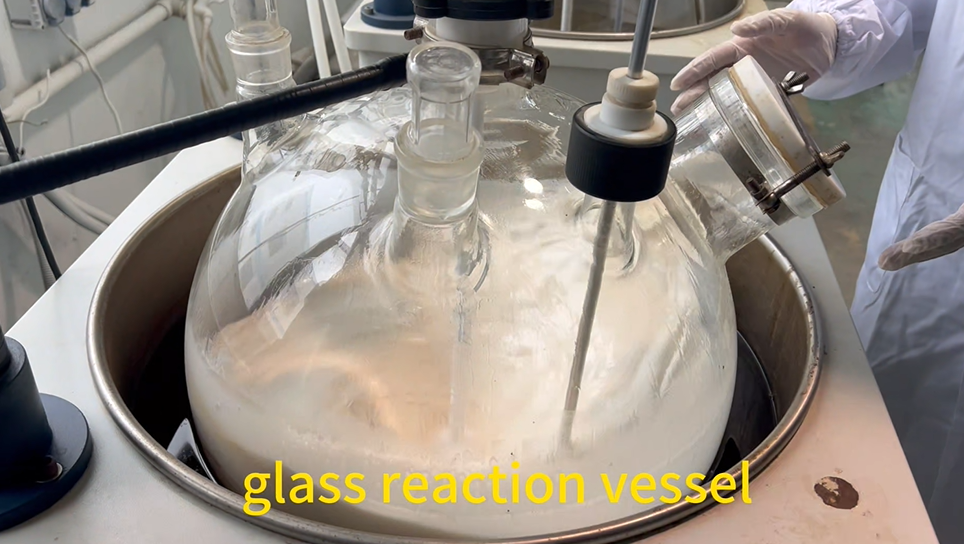

Single glass reaction vessel: core equipment

The core device seen so far is a single glass reaction vessel, which is the main site for the crystallization and purification of LGD4033. By precisely controlling the temperature and solvent ratio, this step encourages the target compound to gradually crystallize in solution. These crystals slowly precipitate in the reaction vessel and eventually change into a separable solid form. This step is crucial because the crystal quality directly affects the purity and yield of the final product.

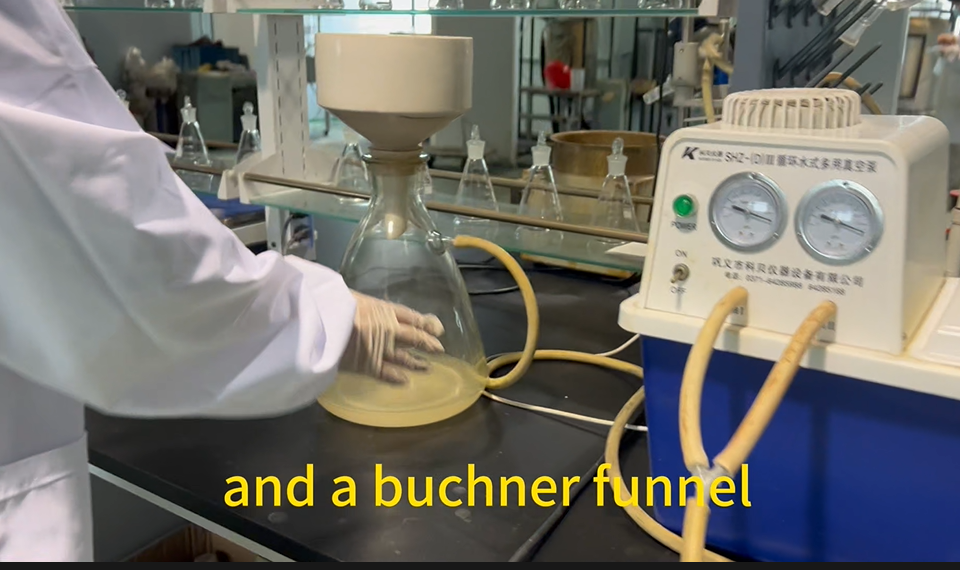

Vacuum filtration: The key to separation and purification

After completing the crystallization step, the next step is to separate the solid LGD4033 from the solvent by vacuum filtration. The required equipment includes:

1. Vacuum pump: provides a negative pressure environment to accelerate the filtration process.

2. Filter bottle: carrying solution and filtered solvent.

3. Brinell funnel: used to support filter paper and undertake crystals.

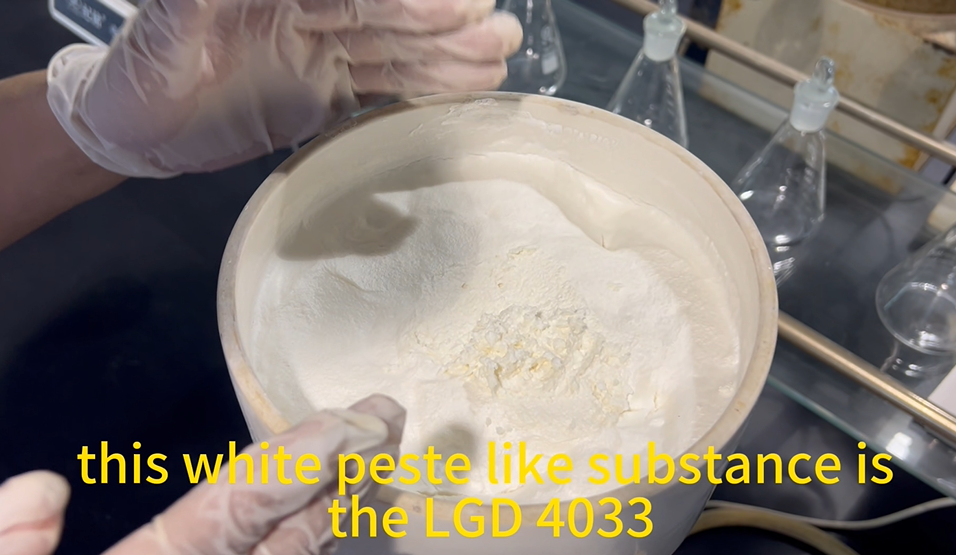

Details of the filtration process:

During the filtration process, the crystallized LGD4033 appears as a white paste substance, which is evenly distributed on the filter paper. The role of the vacuum pump is to quickly draw out the liquid solvent and firmly retain the solid crystal in the Brinell funnel. This procedure is not only efficient, but also minimizes the loss of crystals, thereby increasing the yield of the product.

Dry: The final form of LGD4033

After filtration, the resulting white solids need to be further dried. The purpose of drying is to remove the residual solvent and ensure that the LGD4033 powder reaches the ideal physical state in preparation for subsequent testing and application. This process is usually done by natural drying or low temperature vacuum drying, depending on the physical properties of the product and its intended use.

Solvent interaction in crystallization and purification

It is worth mentioning that the solvent used in the crystallization and purification process is an integral part of the process. Choosing the right solvent and solvent ratio is one of the key technologies, different solvents will affect the rate of crystal formation, crystal shape and final purity. Scientific solvent screening and optimization is an important step to ensure the purification effect.

Purity testing: The ultimate guarantee of quality

Once drying is complete, the LGD4033 powder can be tested for purity. Purity levels can be precisely determined by high performance liquid chromatography (HPLC) or other analytical techniques. Only when strict quality standards are met can these LGD4033 products be packaged and put into use.

Conclusion

The crystallization process of LGD4033 is a process of technical complexity and excellence. From crystallization in the single-layer glass reaction vessel, to separation by vacuum filtration, to the final drying, scientific specifications are strictly followed at every step, ensuring high purity and high quality of the final product. This process demonstrates not only the subtleties of chemical synthesis, but also the ultimate pursuit of quality.

For producers, high quality LGD4033 powder is the core of market competitiveness; For users, choosing products that have been scientifically purified and strictly tested is the best guarantee of safety and effect.